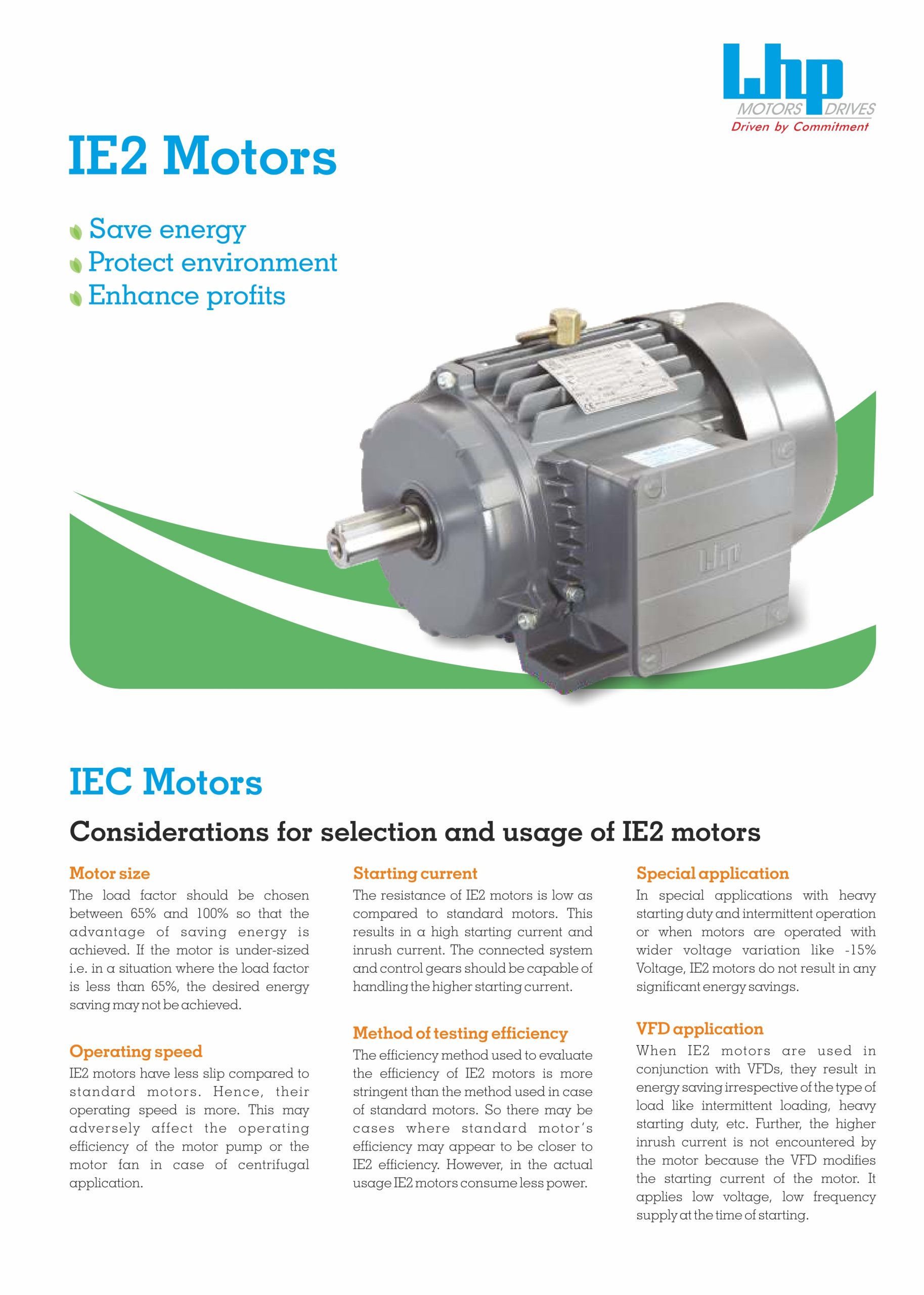

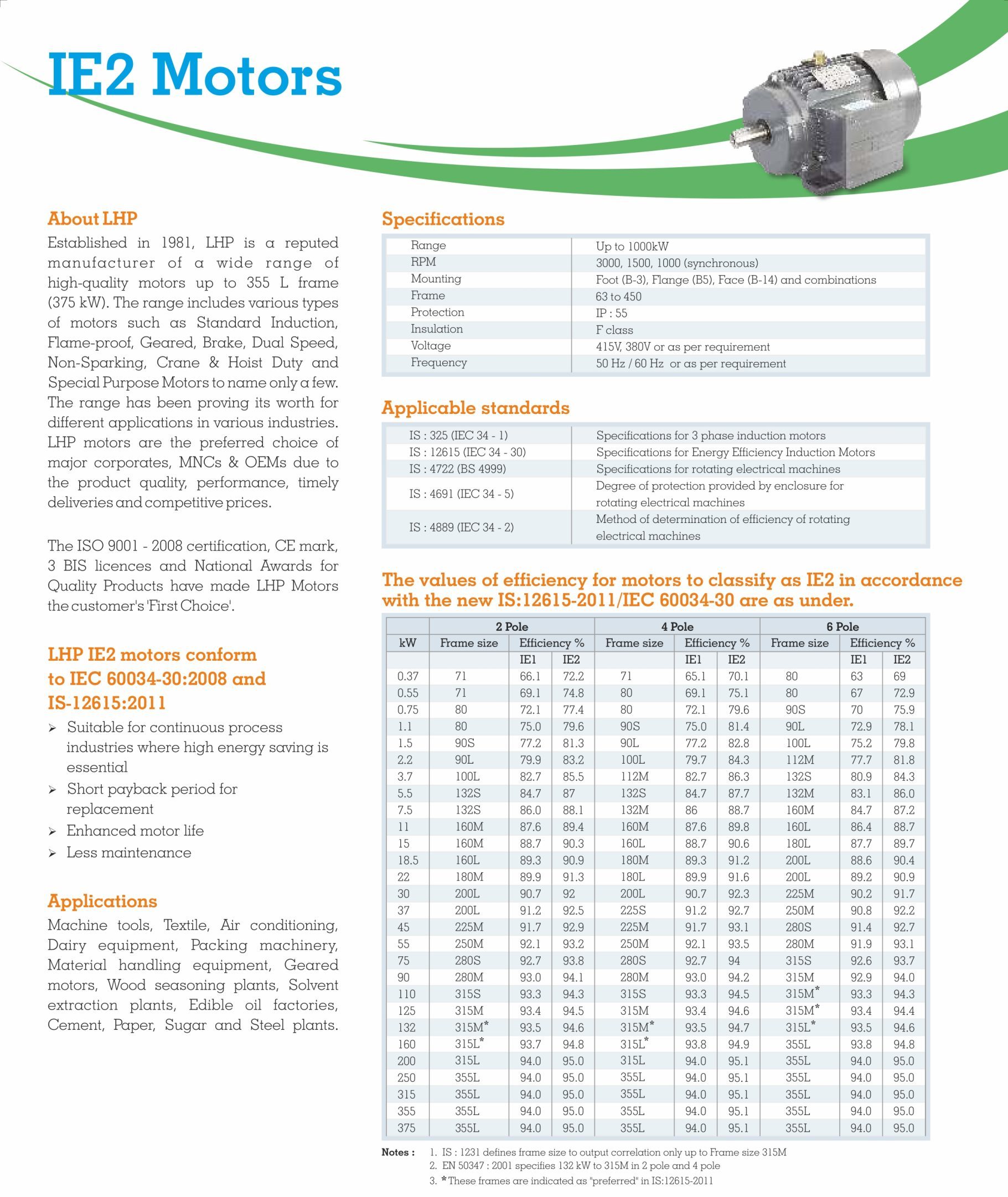

These are High Efficiency Motors and offer good power savings compared to conventional standard motors. The speciality lies in their construction because of the use of different materials. IE2 motors from LHP are developed in accordance with energy-saving guidelines from IEC (IEC/ EN 60034-30-1:2014) and approved by BIS as per the latest IS 12615. These work best in an industrial scenario where motors are not being operated continuously, but the company is looking for a cost-effective option that can save energy and reduce carbon footprint without significantly increasing investments.

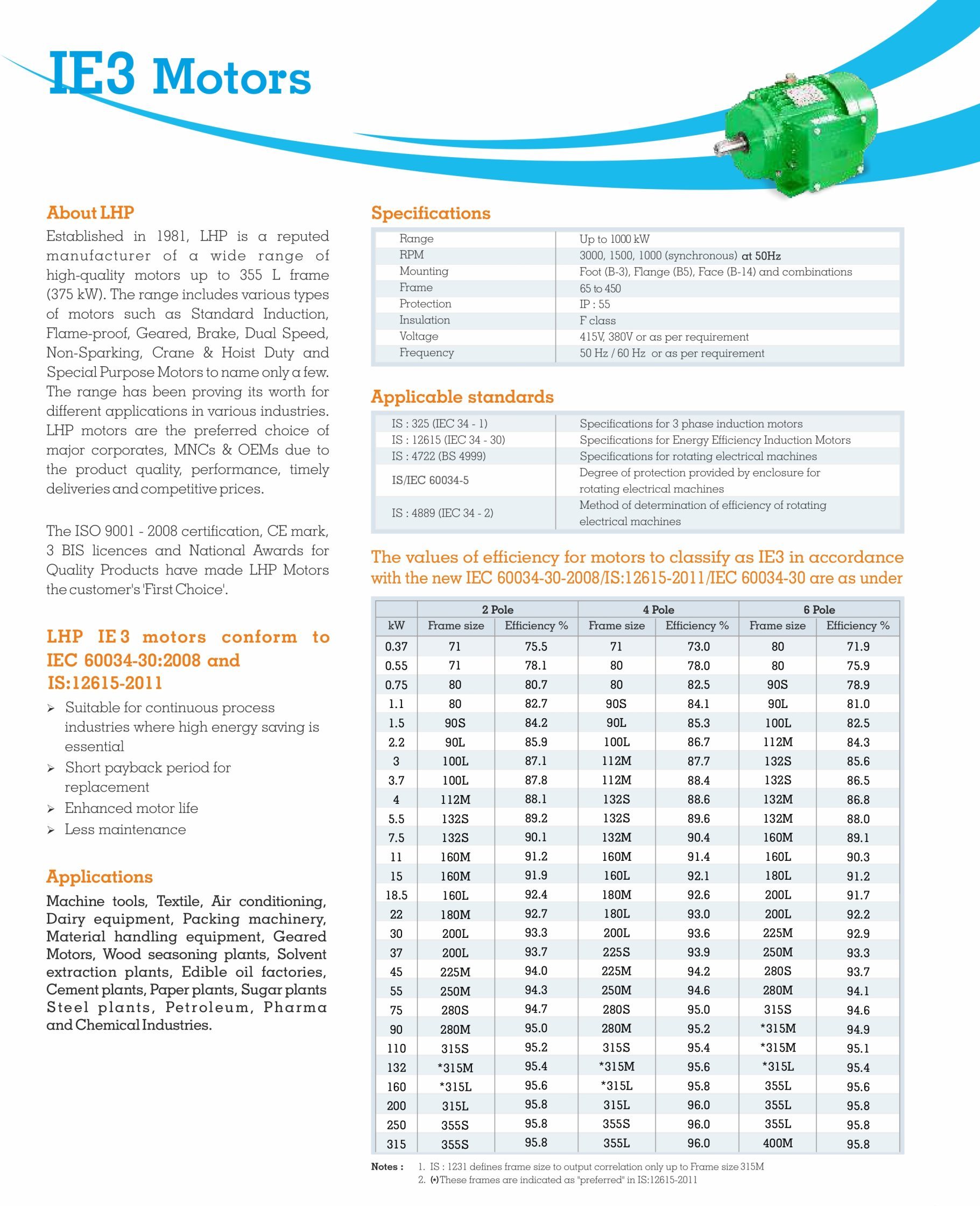

These are also known as Premium Efficiency Motors, which offer slightly lesser power savings as compared to IE4 motors, but much higher savings compared to standard motors. IE3 motors from LHP are developed in accordance with energy-saving guidelines from IEC (IEC/ EN 60034-30-1:2014) and approved by BIS as per the latest IS 12615. These motors are suitable where power costs contribute significantly to the overall operational costs. IE3 motors operate approximately two efficiency bands above IE2 motors, which is equivalent to a 15% reduction in energy losses.

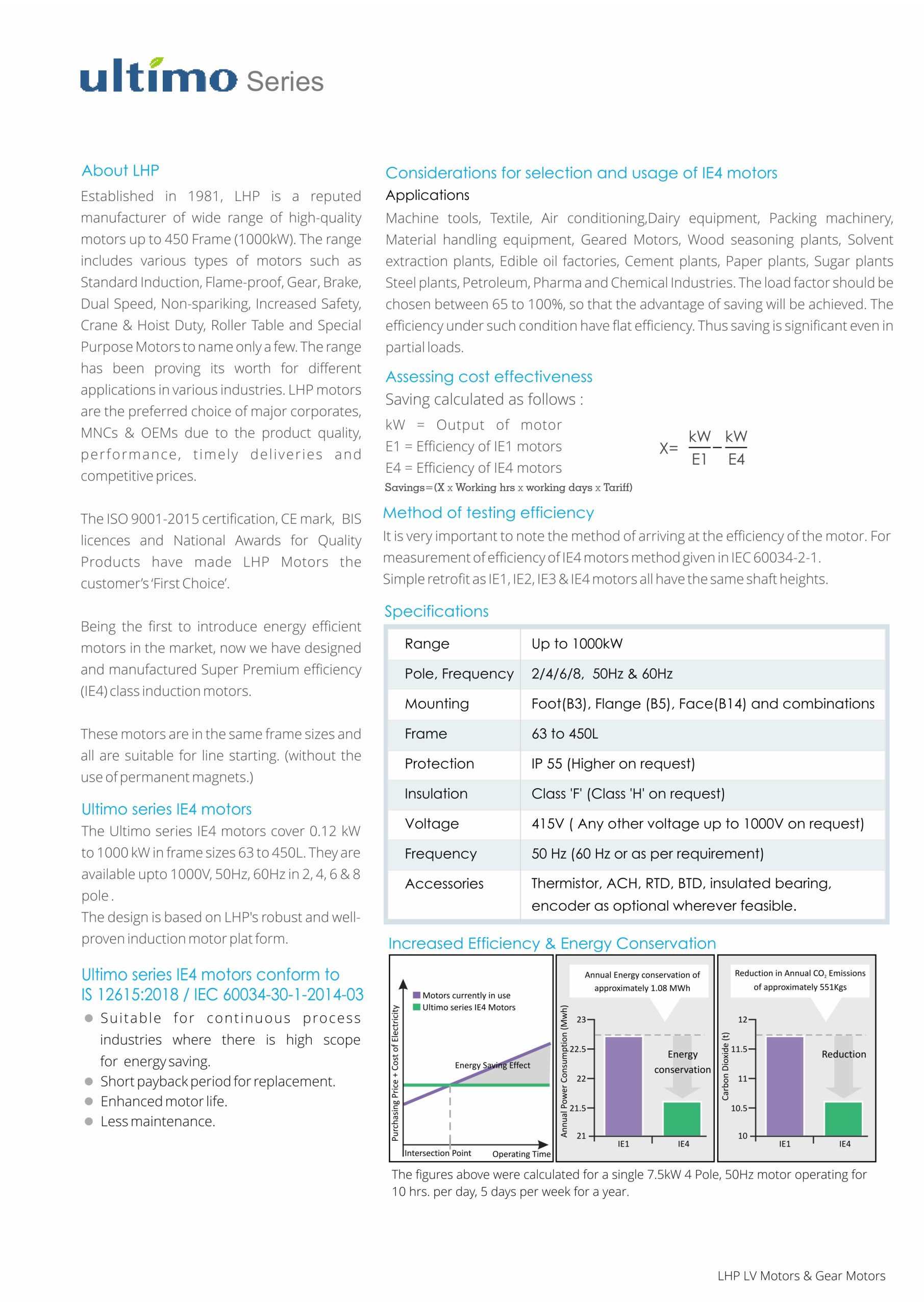

IE4 motors, also known as Super Premium Efficiency Motors, are built around standard 3-phase motors using special materials. They are suitable for a range of applications. IE4 motors from LHP are developed in accordance with energy-saving guidelines from IEC (IEC/ EN 60034-30-1:2014) and approved by BIS as per the latest IS 12615. By using IE4 motors from LHP, one can save significant energy, reduce operating costs and carbon emissions to meet the pollution norms. IE4 motors operate two efficiency bands above IE3 motors, which is equivalent to almost 20% reduction in energy losses. They are recommended where motors operate almost continuously at full load.