MD810 MULTIDRIVE VFD

MD810 is a modular, scalable, easy-to-use product designed for industrial applications requiring complex multidrive systems. Combined with a common rectifier, MD810 forms a multidrive system for complex sectional machines, such as wire drawing, metal processing, calender, textile and chemical fier machinery. MD810 offers a modular design and a common frame size, making it scalable and easy to use. For machines requiring multi-axes servo control, MD810 was designed to work seamlessly with the IS810 servo drive, which matches the common frame size. Peer-to-Peer functionality is included on the drive as standard and includes speed/ position control, load sharing, droop control, and tension control.

InoDriveShop is Inovance’s PC-based software offring. It is based on a familiar Windows™ interface. InoDriveShop can upload and download drive parameters, and features a variety of other functions, such as a real-time oscilloscope.

FEATURES & FUNCTION

- Open and closed loop control For induction and permanent magnet synchronous motors

- Single drive modules: 1.5 to 160 kW – Dual drive modules: 1.5 to 18.5 kW

- Reduced installation costs

- Energy saving, Functional safety – STO SIL3

- Easy & flxible integration,Easy commissioning & maintenance

- Multiple control modes, Advanced functionality

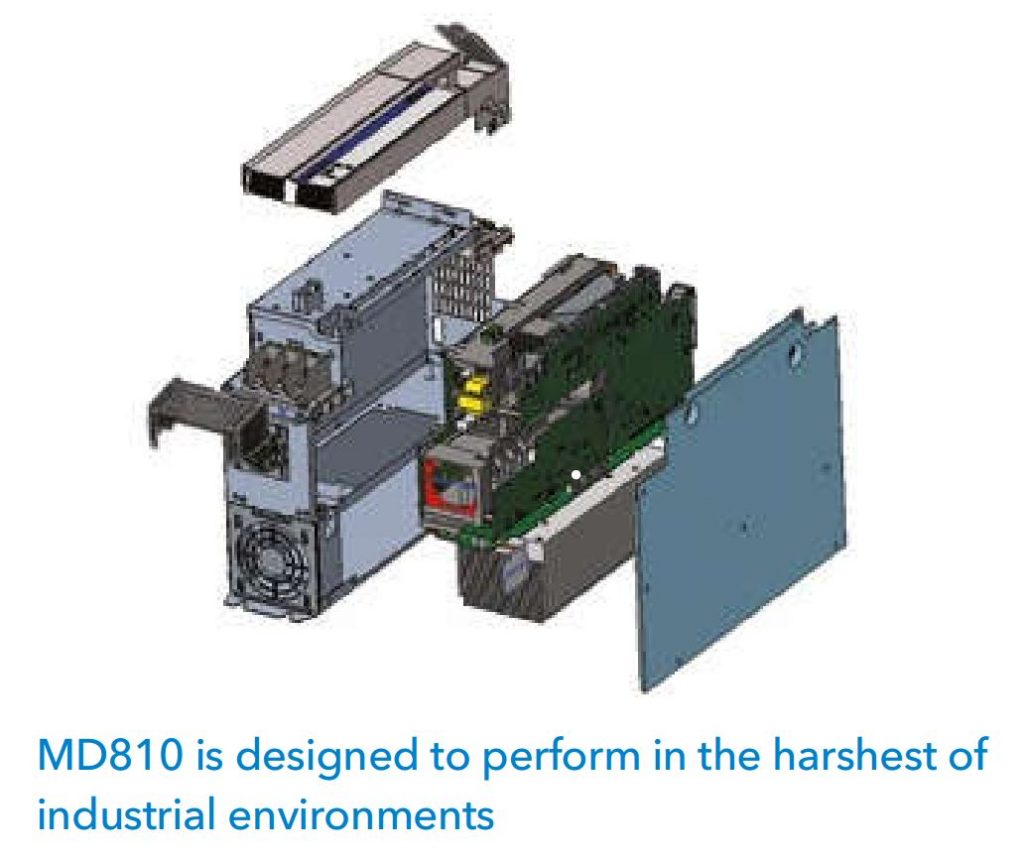

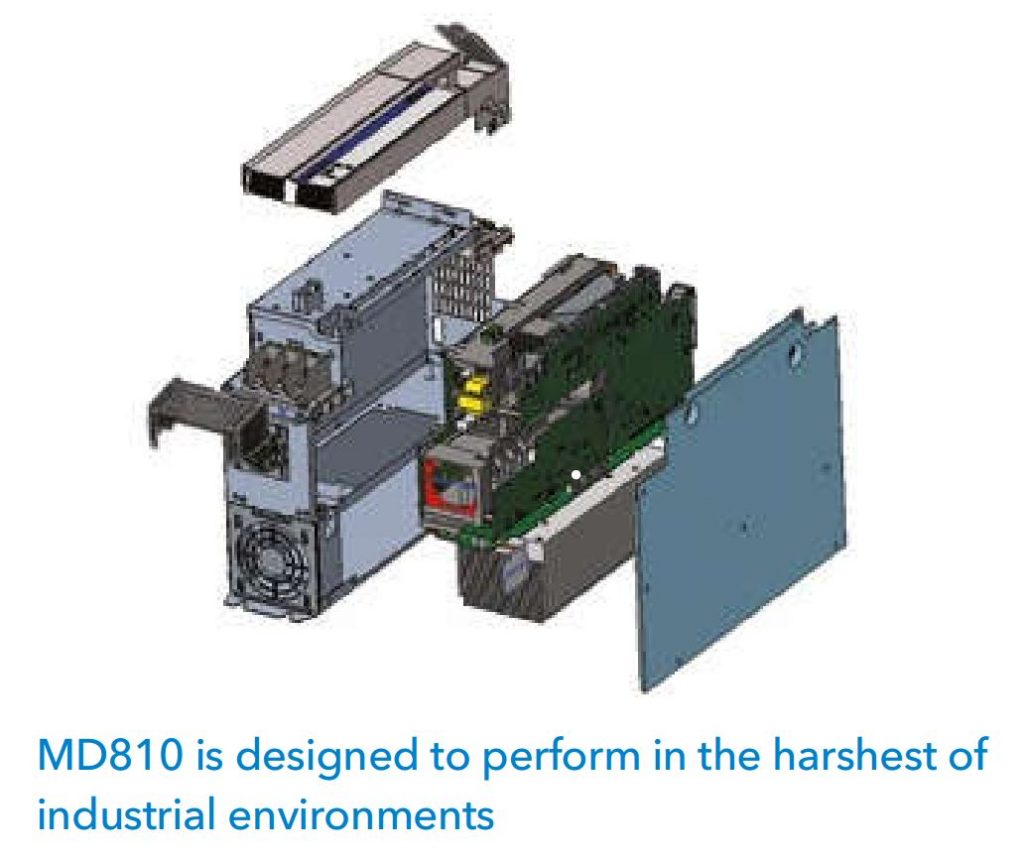

- Designed to be durable

- Common DC bus configuration allows sharing of regenerated energy

- Centralized braking design enables braking energy to be reused

- Class 3C2 & 3S2 conformal coating

- Separate cooling channel for heatsink prevents dust contamination of internal PCBs

- Applicable ambient temperature range – Operation: -10 – 50°C – Storage: -25 – 70°C

- Humidity range of 5%-95% (60% in case of corrosive gas)

- Cost-effctive, built-in DC reactors for smooth current flw and reduced harmonic distortion

- Overload: 150% (for 60 s); 178% (for 2 s)

- Common sizes for each power segment enables fewer inventory components to be stored in customer warehouses

- DC soft charge module enables drive to be independently powered on or off

- Built in redundancy: if one rectifier fails, the system can continue operation with reduced capacity (reduced speed and/ or load)

- PLC/HMI/drive software confiured through the same network for simple maintenance and lower maintenance costs

- Software integrates all steps for commissioning, diagnostics & maintenance

- Improved power effiency results in a smaller cabinet due to reduced rectifier capacity and reduced braking units

- Through-hole mounting further reduces cabinet size/volume

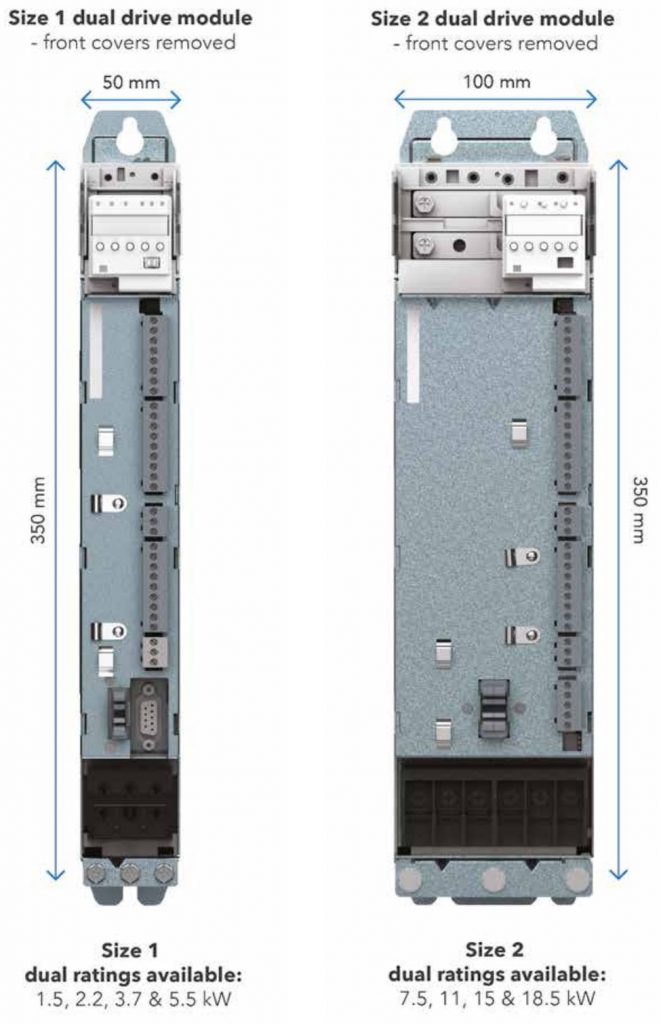

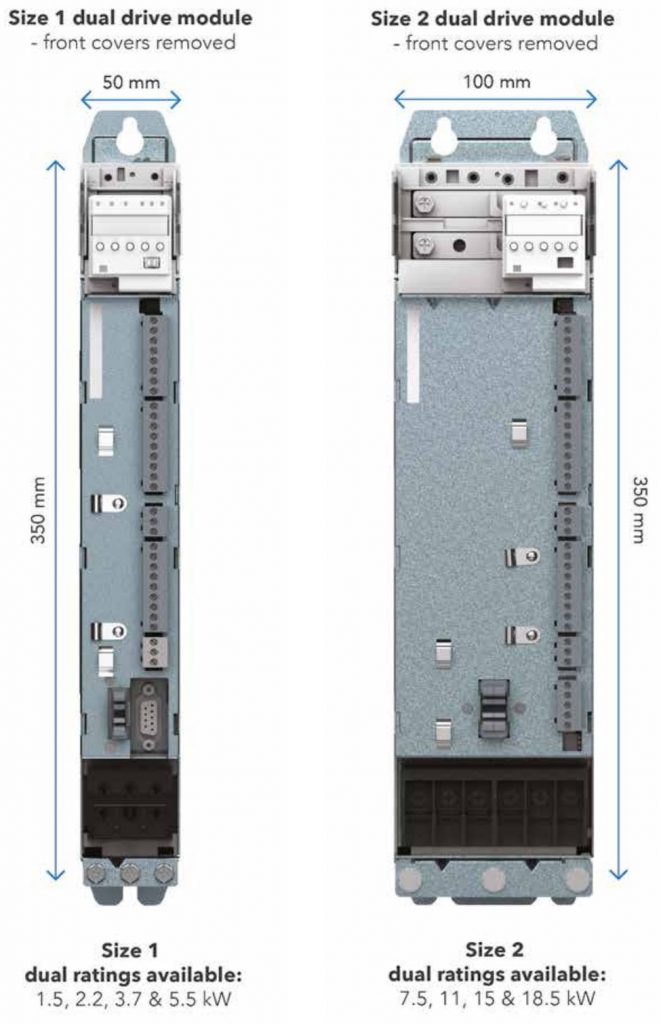

- Compact“2 in 1” dual drive module available for ratings from 1.5 to 18.5 kW

- Simple, plug & play module installation

- DC bus connection accessible from the front for easy module installation

- Safe Torque Of (STO) function eliminates need for output contactors

- Fewer specialist workers required for installation

- Rapid module replacement when needed. One-click network connection with InoDriveShop

- Optimized wiring and commissioning -One PLC connection cable – One group of input power cables – One remote keypad with one cable – connects to multiple drives

- Fewer external components: built-in mini bus bars and common DC bus confiuration enables elimination of external supply components (individual protections, braking units and resistors)

- Compatible with open communication fildbuses like PROFINET, PROFIBUS DP and CANopen

- Control modes: – V/f for open loop induction motors – SVC for open loop induction and PMS motors – FVC for closed loop induction and PMS motors

- Capacity range: 1.5-160 kW (1.5-18.5 kW for dual drive“2 in 1” modules) 3 ph 380-480 VAC voltage supply range

- TN and TT supply, 24 V auxiliary control supply

- Maximum output frequency 500 Hz

- IP20 (IP00 for 355 kW power supply)

- Built-in dynamic brake (for 22 & 45 kW rectifiers)

- Built-in English language LED keypad, Optional remote keypad with 8 GB SD card – Only one keypad needed for multiple drives Parameter copying capability

- Static and dynamic autotuning

- Second PID control for external devices

- Range of peer to peer control modes: – Speed/position control – Load distribution control – Droop control – Tension control

- Center winder/unwinder functionality – Textile wobble control included as standard

- Communication protocols: – Modbus-RTU – CANopen – CANlink – PROFIBUS DP – PROFIBUS DP-to-CANopen gateway – PROFINET-to-CANopen gateway

- PSU unit available from 22 to 355 kW

- Switching frequency up to 12 kHz

- Safe Torque Of (STO) SIL3 (EN 61800-5-2)

- Feedback technologies supported: – Resolver – ABZ incremental encoders – 23 bit serial encoder – unique proprietary Inovance product